Type:

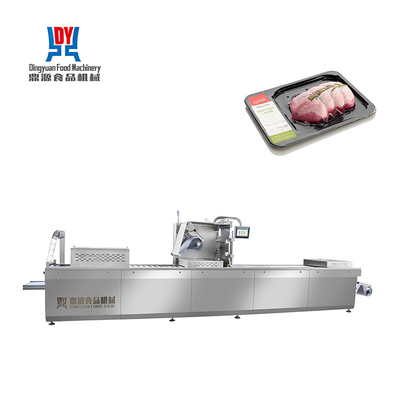

Vacuum Packing Machine

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory, Farms

Showroom Location:

Egypt, Russia

Condition:

New

Application:

Food, Commodity, Medical, Machinery & Hardware, APPAREL

Packaging Type:

Bags, Film, Foil, case

Packaging Material:

Plastic, Metal, Film

Automatic Grade:

Automatic

Driven Type:

Pneumatic

Voltage:

380V

Dimension(L*W*H):

7000*1200*2000mm

Weight:

2000Kg

Warranty:

1 Year

Key Selling Points:

Long Service Life

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Russia

After-sales Service Provided:

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Product name:

Vacuum Skin Packaging Machinery

Usage:

Food Vacuum Package

Chamber type:

Customize

Name:

Vaccum Tray Sealer

Function:

Continuous Vacuum Packing Machine

Keyword:

Vacum Sealing Machine

Packing machine:

Meat Vacuum Packing Equipmet

Material:

SUS304 Food Grade Stainless Steel

Vacuum pump:

BUSCH 100/200

Main Products:

Meat, Beef, Salmon

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!